The Rise of Low-Carbon Aluminum Trailer Manufacturing

What Is Low-Carbon Aluminum?

Low-carbon aluminum is produced using methods that significantly reduce carbon emissions during the manufacturing process. Techniques like recycling aluminum scrap, using renewable energy sources, and optimizing production efficiency play a vital role. This approach not only cuts greenhouse gas emissions but also aligns with the growing demand for environmentally responsible practices in industries like transportation.

The transportation industry is evolving, and aluminum trailers are at the forefront of this shift. With increasing focus on sustainability, manufacturers are turning to low-carbon aluminum to reduce their environmental impact without compromising the quality and durability of their products. Whether it’s flatbed trailers, livestock trailers, bulk trailers, or dump trailers, the use of eco-friendly materials is revolutionizing the way trailers are built and maintained.

What is the production process for Low-Carbon Aluminum?

The production process involves a combination of innovative techniques, including:

- Renewable Energy Sources: Instead of relying on fossil fuels, manufacturers use hydropower, solar, and wind energy to power aluminum smelting plants, drastically cutting greenhouse gas emissions.

- Recycling Aluminum Scrap: Recycling requires only a fraction of the energy used to produce primary aluminum from raw bauxite ore. By incorporating recycled aluminum, the production process becomes significantly more sustainable.

- Advanced Smelting Technologies: Innovations like inert anode technology eliminate carbon emissions during the smelting process, making the aluminum industry cleaner and more efficient.

This shift is driven by the urgent need to lower carbon footprints across industries and meet international climate goals, such as those outlined in the Paris Agreement.

Why Low-Carbon Aluminum Came About

The move toward low-carbon aluminum emerged from the growing awareness of the aluminum industry’s environmental impact. Aluminum production has historically been energy-intensive, contributing significantly to global greenhouse gas emissions. As industries worldwide strive to combat climate change, the demand for sustainable materials has skyrocketed. Here are some key reasons why low-carbon aluminum has become a necessity:

1. Climate Change Awareness

Governments, corporations, and consumers are increasingly prioritizing sustainability. Reducing carbon emissions is a critical step in mitigating the effects of climate change, and industries that fail to adapt risk losing public trust and market share.

2. Regulatory Pressure

Many countries have introduced stricter environmental regulations, pushing manufacturers to adopt cleaner technologies. Carbon taxes, emission caps, and sustainability certifications are driving the adoption of low-carbon alternatives in industries like transportation and construction.

3. Consumer Demand

Consumers are becoming more environmentally conscious, seeking products that align with their values. Low-carbon aluminum trailers appeal to eco-conscious buyers who prioritize sustainability without compromising on performance.

4. Corporate Responsibility

Businesses are increasingly adopting Environmental, Social, and Governance (ESG) criteria to guide their operations. Using low-carbon aluminum demonstrates a company’s commitment to sustainability and responsible practices, enhancing its reputation and competitiveness.

Why Low-Carbon Aluminum Matters for Aluminum Trailers

- Sustainability By choosing low-carbon aluminum, manufacturers are reducing the carbon footprint of trailer production. This is a game-changer for businesses that prioritize sustainability, as it helps them meet regulatory requirements and appeal to eco-conscious customers.

- Strength and Durability Low-carbon aluminum retains all the benefits of traditional aluminum, including its lightweight and corrosion-resistant properties. These qualities are essential for trailers, especially those exposed to harsh weather conditions or heavy loads, like flatbed trailers and bulk trailers. Products like Alumaclear enhance these properties further by offering a clear coat that protects the aluminum against environmental damage, extending its lifespan.

- Cost-Effectiveness While the initial cost of low-carbon aluminum may be slightly higher, its long-term benefits outweigh the investment. Lower maintenance needs, combined with enhanced durability, result in cost savings over the lifespan of the trailer. Applying Alumaclear can further reduce maintenance costs by keeping the surface polished and protected for longer periods.

- Industry Leadership By adopting low-carbon aluminum, manufacturers position themselves as leaders in sustainability, setting a precedent for others to follow. This not only boosts their reputation but also opens up opportunities for partnerships and certifications that reward environmentally friendly practices.

Protecting Your Low-Carbon Aluminum Trailer

To ensure the longevity of low-carbon aluminum trailers, proper care and maintenance are crucial. Here’s how you can protect your investment:

- Trailer Washing: Regular washing helps remove dirt, grime, and salt, preventing corrosion and maintaining the trailer’s appearance.

- Clear Coat and Protective Wraps: Applying a clear coat or clear protective wrap offers an extra layer of protection against UV rays, scratches, and environmental damage. Products like Alumaclear provide top-notch protection, keeping your aluminum trailer in pristine condition.

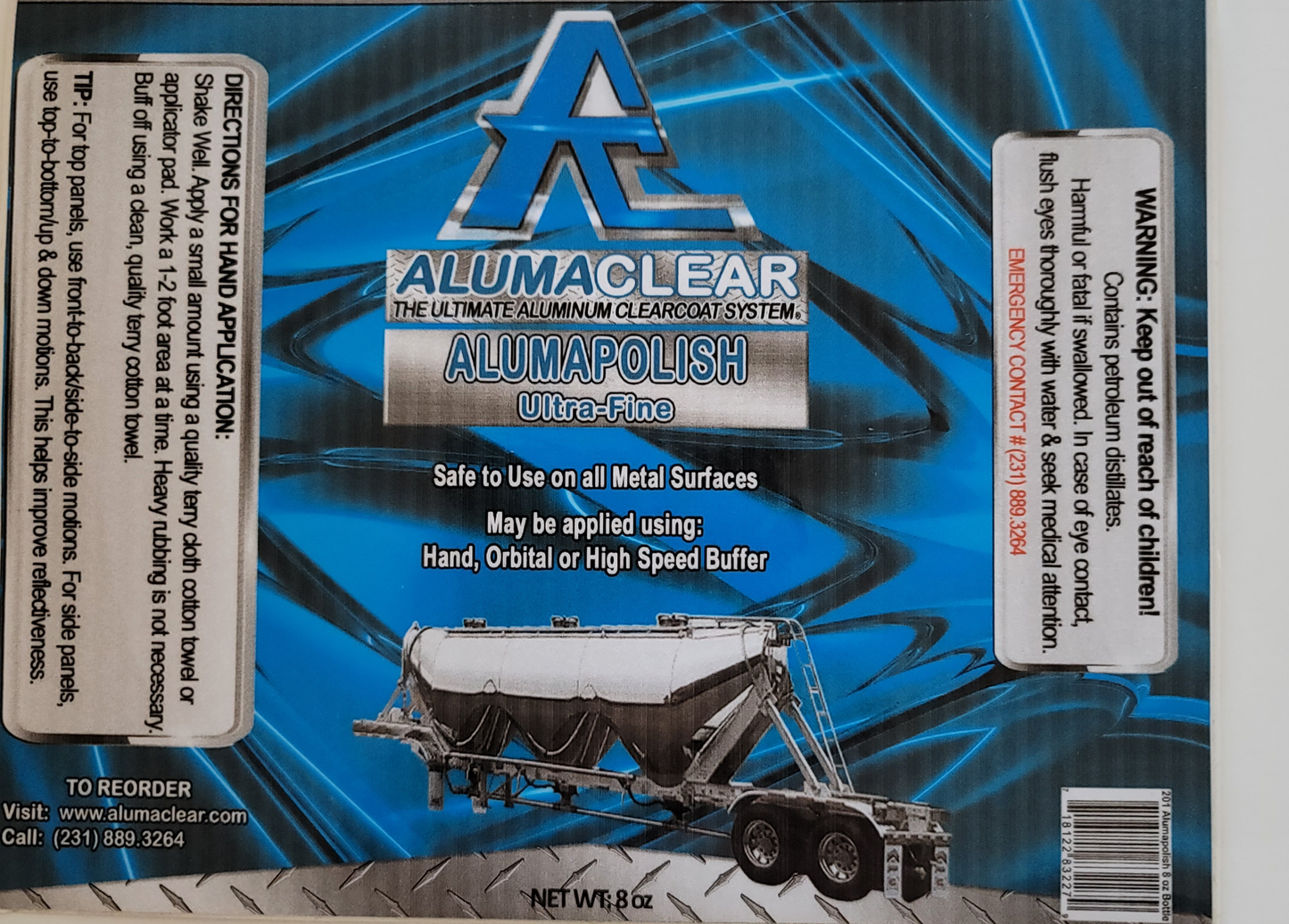

- Aluminum Polish: Using a high-quality aluminum polish ensures your trailer’s surface stays smooth and shiny, enhancing its overall appeal.

- Wheel Maintenance: Don’t forget about the wheels! Keeping them polished and clean not only improves aesthetics but also prolongs their lifespan.

The Future of Trailer Manufacturing

The adoption of low-carbon aluminum is a significant step forward in making trailer manufacturing more sustainable. Flatbed trailers, livestock trailers, dump trailers, and bulk trailers are already benefiting from this innovation, which combines eco-friendly materials with superior performance. By pairing low-carbon aluminum with advanced protective solutions like Alumaclear clear coats and wraps, manufacturers are setting new standards for durability, efficiency, and sustainability.

Join the Conversation

What are your thoughts on the use of low-carbon aluminum in trailer manufacturing? Do you think this shift will become a standard in the industry? How do you maintain your aluminum trailers to ensure their longevity? Share your opinions and experiences in the comments below—we’d love to hear from you!

Share

Related Posts

-

Diesel Day 2025 Saturday June 14th

Everyone’s Welcome at Diesel Day! Join us for Diesel Day and immerse yourself in the excitement of truck shows, diese...

-

Best Aluminum Protective Coating

What are the Best Aluminum Protective Coatings? Keeping Your Aluminum & Metal Looking Its Best Is your aluminum l...

-

Best Aluminum Polish and Clear Coat Protection for Alloy Wheels

There's something undeniably satisfying about a vehicle with gleaming wheels. Whether you're rolling on custom alloy ...

-

Keeping Your Aluminum Boat in Top Shape: Protection & Shine

How do you keep your aluminum boat looking shiny and protected year after year? Aluminum boats are built for adventur...

-

10 Ways To Improve Your Aluminum Trailer in 2025

Aluminum trailers are known for their durability, lightweight design, and resistance to rust, making them a top choic...

-

How to Protect and Maintain Aluminum Trailers

How to Protect and Maintain Aluminum Trailers: Expert Tips for Bulk, Livestock, Flatbed, and Feed Trailers Aluminum t...

-

Can You Clear Coat Over Polished Aluminum Parts?

TLDR Can You Clear Coat Over Polished Aluminum Parts? Polished aluminum parts are widely used in industries like auto...

-

What is the best clear coat for aluminum wheels?

What is the best clear coat for Aluminum Wheels? Alumalcear is protecting and enhancing your aluminum wheels with th...

-

Clear Coating vs. Wax Treatments: Choosing the Best for Your Vehicle

Clear Coating vs Wax Treatments: Which is Best for Your Vehicle? In the world of automotive care, maintaining the pri...

-

Stainless Steel Elevator Protection for Hospitals & Hotels

TLDR: Alumaclear is now offering advanced anti-microbiological services for stainless steel elevators in hospitals a...

-

Clear Coating Your Electric Vehicle: Best Protection for Aluminum

TLDR: Why should you clear coat your electric vehicle (EV)? Clear coating protects your EV’s aluminum surfaces from c...

-

Alumaclear and Alumawrap for Dickson Township Fire Department

In the Heart of Brethren, MI: The Dickson Township Fire Department's Partnership with Alumaclear and Alumawrap In Bre...

-

Let’s Be Clear: What Is Clear Coat?

Let’s Be Clear: What Is Clear Coat? Your vehicle's exterior paint likely has three layers. The bottom layer is called...

-

Ceramic Coating vs. Polishing: Which is Best for Your Vehicle?

If you’re new to the world of vehicle care, you’ve probably heard about ceramic coating and polishing. But what are t...

-

Transform Your Fleet with Alumaclear!

When it comes to maintaining your fleet's aluminum, choosing the right care solution is key to keeping vehicles looki...

-

The Benefits of Using a Professional Sprayer

When it comes to maintaining the pristine condition of your vehicles and equipment, using the right tools can make al...

-

Common Mistakes to Avoid When Cleaning Aluminum Surfaces

Cleaning aluminum surfaces may seem straightforward, but without the right approach, you could end up doing more harm...

-

How to Protect Your Vehicle from Harsh Weather Conditions

When it comes to keeping your vehicle in top shape, harsh weather conditions can be a significant challenge. Whether ...

-

Unleash the Full Potential of Your Boat with Alumapolish: The Ultimate Guide to Polishing Boats in 2024

When it comes to maintaining your boat, especially those beautiful 2024 tri-toons gliding across the Great Lakes, the...

-

Why Alumawrap is the Perfect Choice for Vehicle Protection and Branding

When it comes to protecting your vehicle and making a statement on the road, Alumawrap® is your go-to solution. Wheth...

-

Top 10 Tips for Maintaining the Shine on Your Aluminum Wheels

Top 10 Tips for Maintaining the Shine on Your Aluminum Wheels Maintaining the shine on your aluminum wheels is essent...

-

Why Polishing Your Aluminum Surfaces is Essential

The Ultimate Guide to Polishing Your Aluminum Surfaces: Why Alumapolish Sets the Gold Standard Polishing your vehicle...

-

The Ultimate Protection: Ceramic Coating for Commercial Vehicles, Big Rigs, Boats, and Cars

Keeping your vehicle in pristine condition is a top priority, whether you own a commercial fleet, a big rig, a boat, ...

-

TCI 503 and TCI 710: Revolutionizing Vehicle Protection

When it comes to maintaining and protecting aluminum surfaces, two products stand out: TCI 503 and TCI 710. Each of t...

-

Why Maintaining Your Vehicle’s Shine is Essential for Longevity and Value

Why Maintaining Your Vehicle’s Shine is Essential for Longevity and Value Your vehicle is more than just a mode of tr...

-

Alumaclear Racing: Keeping the Factory Shine on the Fast Track

Alumaclear Spray Can: Instant Protection, Lasting Results The Alumaclear Spray Can is a staple in our maintenance ar...